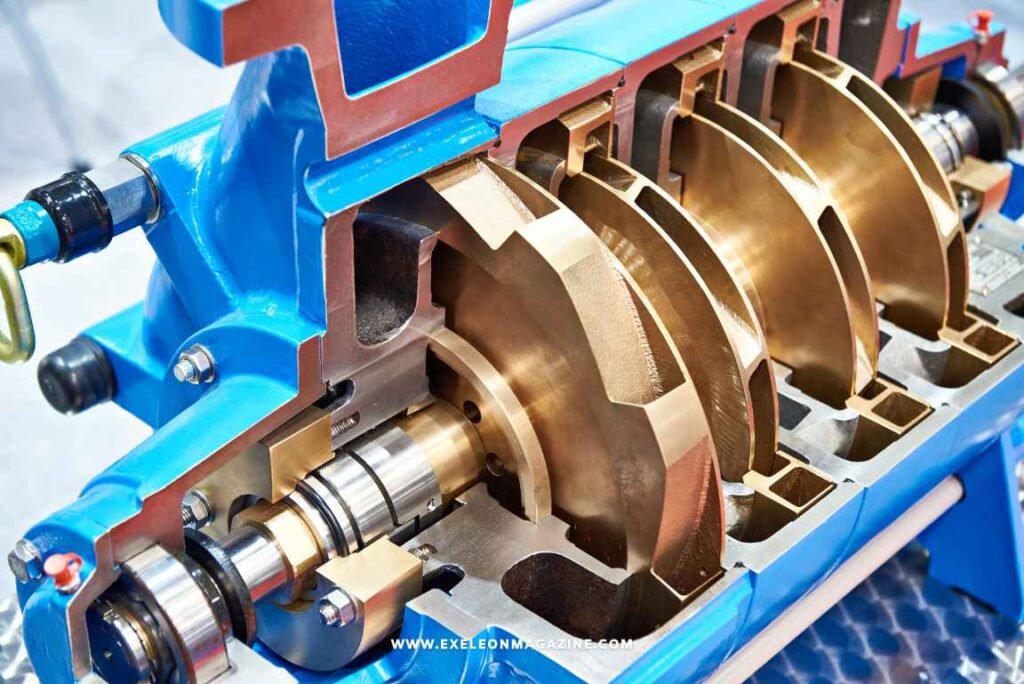

Introduction to Industrial Centrifugal Pumps

Industrial centrifugal pumps are vital for fluid movement, especially within the chemical industry. They function by transforming rotational kinetic energy into hydrodynamic energy, utilizing an impeller to propel fluid through a system. Their inherent simplicity, dependable nature, and versatility in handling diverse liquids make them an indispensable element in chemical manufacturing machinery.

Centrifugal pumps are crucial for chemical operations, providing a scalable and cost-effective solution where precision, safety, and efficiency are essential. With the industry’s increasing focus on sustainability and operational excellence, the importance of industrial centrifugal pumps continues to grow.

The Role of Centrifugal Pumps in the Chemical Industry

The chemical industry requires the continuous, controlled transfer of a wide range of fluids, some of which may be volatile, corrosive, or highly viscous. This is where centrifugal pumps in the chemical industry play a critical role.

These pumps support key operations such as:

- Mixing and blending chemicals

- Transferring fluids between processing stages

- Loading and unloading chemical containers

- Circulating process fluids through heat exchangers

Their ability to operate consistently under harsh conditions makes centrifugal pumps ideal for supporting the complex workflows found in chemical manufacturing plants. Furthermore, their adaptability ensures compatibility with a variety of chemicals, from acids and solvents to slurries and corrosive mixtures.

Types of Chemical Process Pumps and Their Applications

Choosing the right type of pump is essential to ensure process efficiency and safety. Within chemical facilities, several types of chemical process pumps and chemical transfer pumps are used based on specific application requirements.

- End-suction centrifugal pumps: Widely used for general chemical handling where moderate flow and pressure are required.

- Magnetically driven pumps: Ideal for handling hazardous or toxic fluids, as they eliminate the need for mechanical seals, reducing leakage risk.

- Self-priming centrifugal pumps: Common in transfer operations where the pump may need to draw fluid from a below-grade source.

- Vertical centrifugal pumps: Useful in applications with limited floor space or where submersion is necessary.

Each type of pump plays a unique role in optimizing fluid dynamics and process safety. Matching the correct pump to the chemical application’s requirements is critical to minimizing downtime and maximizing output.

Corrosion-Resistant Centrifugal Pumps: Enhancing Durability

One of the most crucial considerations when selecting pumps for chemical applications is their corrosion resistance. Many chemical substances are highly aggressive and can quickly degrade standard pump materials.

Corrosion-resistant centrifugal pumps are built using materials such as:

- Stainless steel

- Hastelloy

- Polyvinylidene fluoride (PVDF)

- Polytetrafluoroethylene (PTFE)

These materials offer excellent resistance to chemical attack, enabling pumps to operate safely and reliably over extended periods. Corrosion resistance not only improves safety but also reduces maintenance frequency and extends equipment life, key elements in achieving long-term cost efficiency.

By minimizing chemical interaction with pump internals, corrosion-resistant pumps support stable flow rates, preserve product purity, and reduce the risk of unscheduled plant shutdowns.

Boosting Performance with High-Efficiency Industrial Pumps

Efficiency is a major concern in modern chemical production. Energy usage in pumping systems often represents a significant portion of a plant’s operating costs.

Investing in high-efficiency industrial pumps can lead to measurable gains in both energy consumption and production uptime.

Efficiency enhancements are achieved through:

- Optimized impeller design for better flow dynamics

- Improved hydraulic balancing to reduce energy loss

- Variable frequency drives (VFDs) that allow real-time flow adjustments

- Low-friction components to minimize wear and improve throughput

When integrated into a larger process system, these pumps contribute to overall industrial pump efficiency by ensuring that energy is not wasted and that processes run smoothly even under variable load conditions.

Integration in Process Fluid Transfer Systems

The effectiveness of a pump does not exist in isolation. To achieve maximum output and safety, centrifugal pumps must be properly integrated into process fluid transfer systems.

A well-designed system includes:

- Proper pipe sizing and routing to avoid pressure losses

- Flow sensors and control valves for precise regulation

- Surge protection and check valves to handle pressure fluctuations

- Monitoring tools for real-time performance tracking

In chemical plants, integration often involves syncing pump operation with automated control systems. This enables operators to dynamically adjust flow rates according to production needs while monitoring temperature, viscosity, and chemical composition.

By optimizing the entire transfer system, not just the pump, manufacturers can improve efficiency, reduce manual intervention, and respond faster to operational issues.

Key Factors in Selecting the Right Chemical Handling Pump

Selecting the correct chemical handling pump requires a thorough evaluation of the application’s specific requirements. Failing to consider critical factors can result in underperformance, equipment failure, or safety hazards.

Important selection criteria include:

- Fluid characteristics: Is the fluid corrosive, abrasive, or volatile?

- Viscosity and temperature: High-viscosity fluids require specialized impellers and materials.

- Flow rate and pressure requirements: Accurate calculation ensures the pump can handle the system’s demand.

- Seal requirements: For hazardous fluids, seal-less or magnetic drive designs are preferable.

- Material compatibility: Ensures long-term performance and chemical resistance.

Engineers and maintenance teams must work closely to evaluate process parameters and select pumps tailored to the unique demands of each application.

Emerging Trends in Centrifugal Pump Applications

As the chemical industry evolves, new technologies and practices are reshaping how centrifugal pump applications are approached. Several trends are helping organizations enhance efficiency, reduce environmental impact, and gain better control over production processes.

Smart pump technologies now enable real-time diagnostics and predictive maintenance. Sensors embedded within pumps can detect early signs of wear, cavitation, or seal failure, allowing for proactive repairs before costly breakdowns occur.

In addition, new composite and engineered materials are being developed to improve chemical resistance while lowering weight and maintenance complexity. These materials also function better in harsh temperatures and high pressure environments.

Energy recovery and closed-loop controls are also gaining popularity. These solutions cut energy use and help a facility achieve its overall sustainability goals.

Maintenance Best Practices for Longevity

Regardless of how advanced or efficient a pump is, consistent maintenance is crucial to keep it running smoothly and safely. Following best practices can prevent premature failures and preserve industrial centrifugal pump efficiency.

Key maintenance tips include:

- Regular inspections: Check for leaks, vibrations, and unusual noises.

- Lubrication schedules: Keep bearings and moving parts well-lubricated.

- Alignment checks: Ensure shafts and motors remain correctly aligned.

- Seal inspections: Replace worn or damaged seals to avoid fluid leakage.

- Performance monitoring: Track pressure, flow, and energy use to detect anomalies.

Establishing a predictive maintenance schedule based on operational data can further reduce the risk of unplanned downtime, especially in critical chemical processes where interruptions can have costly ripple effects.

Conclusion: The Future of Industrial Centrifugal Pumps in the Chemical Sector

As chemical manufacturing evolves and becomes more energy-conscious, industrial centrifugal pumps will continue to play a crucial role. These pumps are more than just mechanical equipment; they are strategic assets for contemporary chemical processes, featuring efficient fluid movement, corrosion resistance, and the ability to interact with sophisticated control systems.

Investing in high-quality, properly designed pumps improves plant dependability, lowers operational costs, and aligns with industry standards for safety and sustainability. Moving forward, advances in smart technology and materials science will enhance pump performance, solidifying their position as essential components of the chemical industry’s future.